Dynamic fermentation and the making of non-alcoholic beers

The market for non-alcoholic beer is growing rapidly worldwide. The main factors driving this trend are lifestyle changes, increased health consciousness and the rising popularity of “mindful drinking”. In response, more and more breweries are expanding their portfolios to include non-alcoholic options.

Two approaches to production

There are a number of methods for producing non-alcoholic beer, which essentially fall into two categories: either the beer is prevented from producing alcohol in the first place or alcohol is removed from finished beer after fermentation. Each approach will entail different processes. Breweries opting to remove alcohol from beer post-fermentation must first invest in new, specialised dealcoholisation equipment. The established methods in this category are thermal processes (distillation) and membrane separation. By contrast, methods that prevent alcohol from being produced in the first place are relatively easy to implement. Fermentation is interrupted before the beer reaches more than 0.5% alcohol by volume.

New technology uses crabtree-negative yeasts

For some time now, a special group of yeasts known as crabtree-negative has been gaining in popularity. Just like traditional brewer’s yeasts, they metabolise the sugars contained in the wort into alcohol – but only in an anaerobic environment. Unlike their traditional counterparts, once oxygen comes into play (in other words, in an aerobic environment), they stop producing alcohol. They continue to generate aroma compounds, but no alcohol. The aroma compounds mask the wort flavours that are often typical of non-alcoholic beers, to the extent that consumers no longer notice them. Thus, when an aerobic environment is maintained throughout fermentation, beers with 0.0% alcohol by volume (ABV) can be produced.

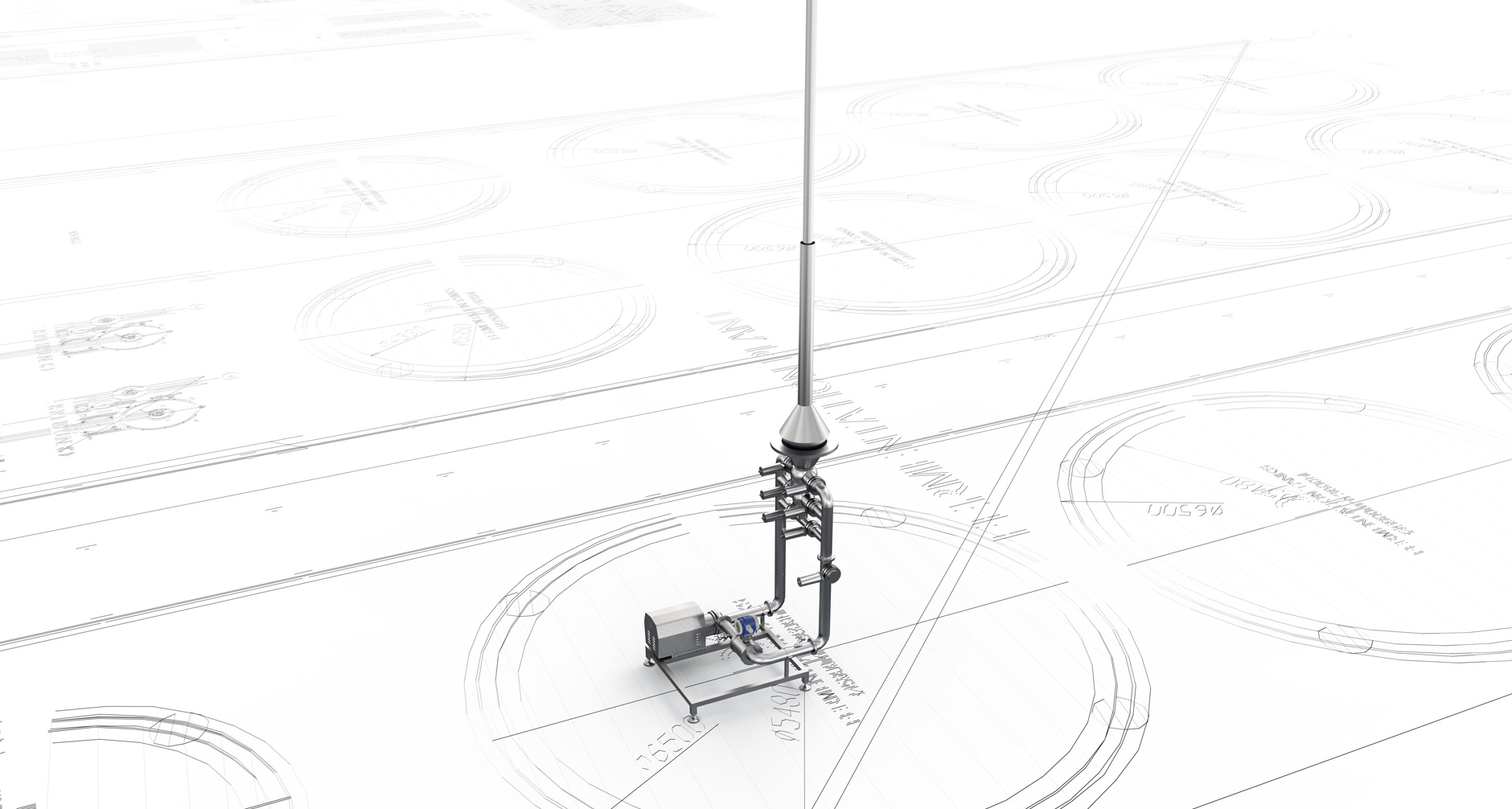

New variant of Poseidon with integrated aeration and oxygen sensor

This is where Steinecker’s Poseidon recirculation unit comes into play. With it, various circulation zones and flows can be established within the tank. The result is an even, efficient fermentation process that, in turn, is the key to producing high quality beer.

In order to use its Poseidon recirculation unit with crabtree-negative yeasts, Steinecker developed a variant featuring an integrated aeration system and oxygen sensor. Here, too, recirculation keeps the yeast in a more homogeneous suspension in the beer, which in turn improves flavour development and speeds maturation. Even more important, though, is its use for aerating the tank: During the maturation process, Poseidon recirculates the wort continuously and maintains a consistent oxygen content of between 1.0 and 1.5 parts per million (ppm). To develop the desired aroma profile, it is important that a high temperature be maintained for as long as possible – all the while in an aerobic environment. In trials conducted in the Steinecker Technology Centre in collaboration with Novenesis, a producer of crabtree-negative NEER yeasts, these conditions could be maintained for well over 20 hours using Poseidon. In the end, these tests produced fully flavoured beer containing 0% alcohol in just two days’ time.

Download