While sales of conventional beer have been declining for years, the non-alcoholic segment is growing steadily. More and more craft breweries are seizing the trend and bringing their own non-alcoholic varieties to market. In order to be called such, a beer must have less than 0.5% alcohol by volume (ABV). There are a number of methods for producing it, which essentially fall into two categories: either the beer is prevented from producing alcohol in the first place or alcohol is removed from finished beer after fermentation.

Most commonly, fermentation is interrupted before the beer has reached more than 0.5%

- Most commonly, fermentation is interrupted before the beer has reached more than 0.5% alcohol by volume. In such processes, the yeast is pitched (added to the wort to start fermentation) at a temperature right around 5.0 degrees Celsius. The aim here is to achieve slow, controllable fermentation. The longer the yeast and wort can be kept in contact with each other before the alcohol content reaches its limit, the more unwanted wort flavors can be reduced.

- Cold contact fermentation, in which the yeast is pitched at very low temperatures below 0.0 degrees Celsius, produces almost no alcohol at all. However, the wort must be kept in continuous motion to ensure that the yeast remains in suspension so that the wort flavors can be sufficiently reduced.

- A simple way of producing non-alcoholic beers is to use maltose-negative yeasts, which can metabolize glucose, fructose and saccharose but not maltose.

Because this process always results in a high residual extract, these beers need to be pasteurized to prevent possible bursting of bottles down the line.

Breweries opting to remove alcohol from beer post-fermentation must first invest in new, specialized equipment. The most established methods are thermal processes (distillation) and membrane separation.

- The distillation is done under a vacuum, which lowers the evaporation temperature. Flavor can be recaptured from the resulting vapors and from the carbonation, which was removed prior to distillation, and added back into the now-alcohol-free beer.

- Membrane separation using reverse osmosis is especially well suited for bottom-fermented beers. Here, high pressure is used to force the beer through a semi-permeable membrane, which separates out the alcohol. This process does not subject the beer to any thermal stress, the result of which is higher beer quality. However, it requires the most energy and water of all the processes mentioned, especially when the alcohol by volume (ABV) needs to be brought below 0.05%.

New technology uses crabtree-negative yeasts

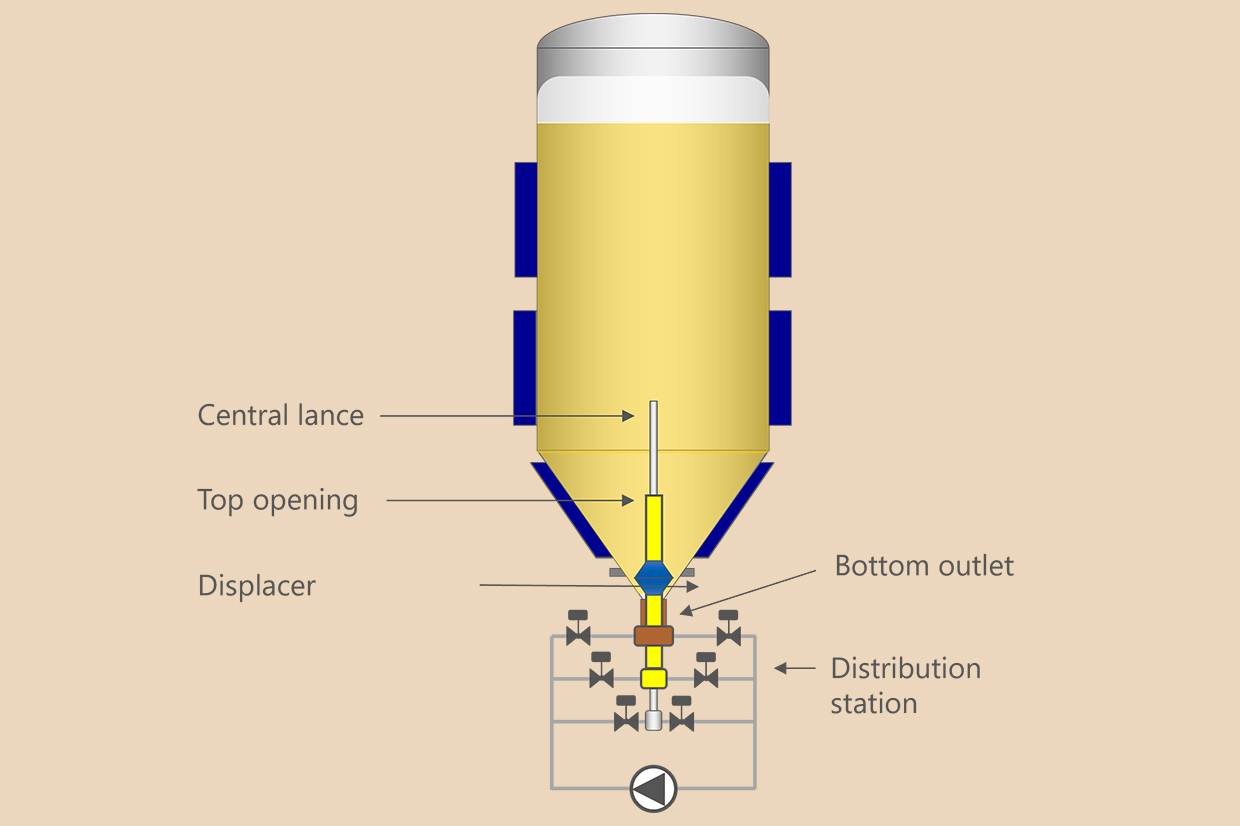

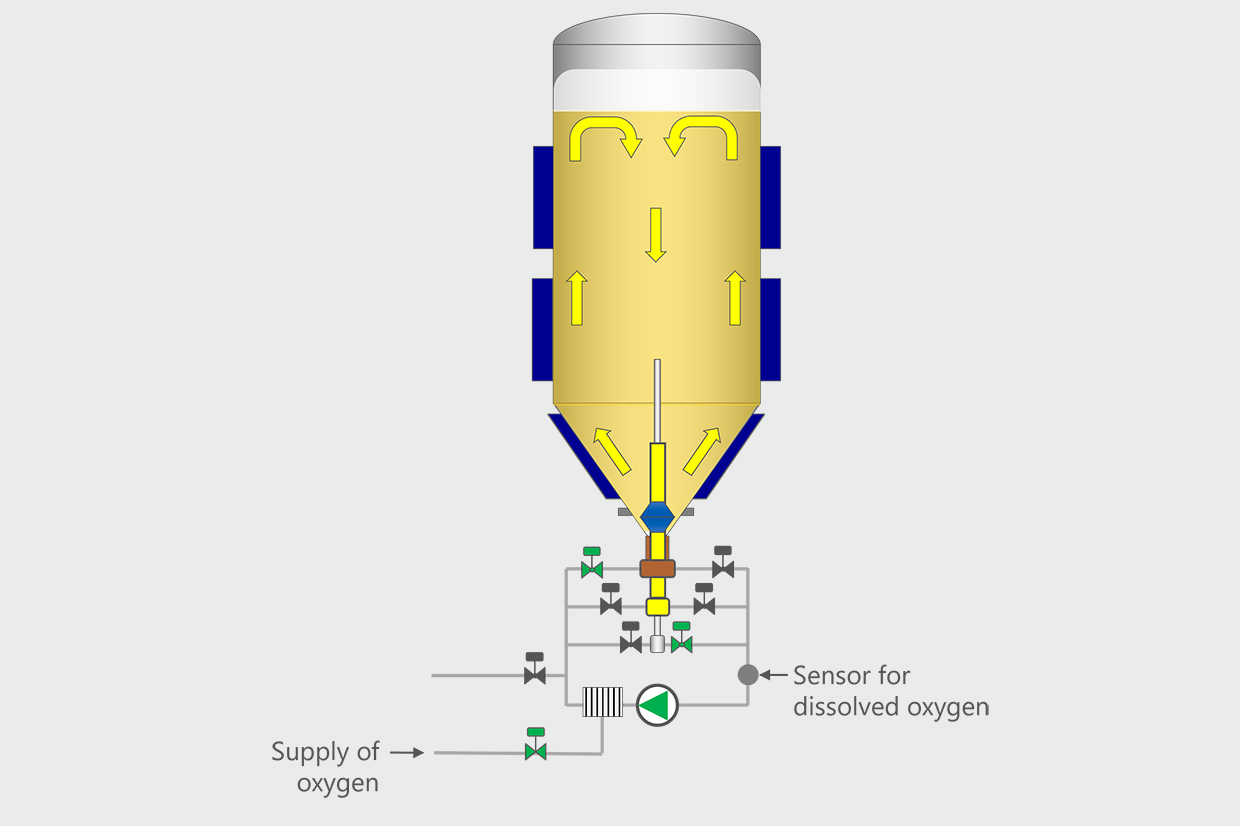

For some time now, a special group of yeasts known as crabtree-negative has been gaining in popularity. Just like traditional brewer’s yeasts, they metabolize the sugars contained in the wort into alcohol – but only in an anaerobic environment. Unlike their traditional counterparts, once oxygen comes into play (in other words, in an aerobic environment), they stop producing alcohol. They continue to generate aroma compounds, but no alcohol. The aroma compounds mask the “worty” aromas that are often typical of non-alcoholic beers, to the extent that consumers no longer notice them. Thus, when an aerobic environment is maintained throughout fermentation, beers with 0.0% alcohol by volume (ABV) can be produced. In order to ensure aerobic conditions throughout the entire fermentation, the tank must be continuously aerated. For fermentation tanks, which of course are designed to provide an anaerobic environment, this poses a challenge.